We invite you to take a look at our various production workshops. Follow the guide!

Materials preparation and rubber workshops

In the materials preparation workshop, we process the materials used in rubber processing and flexible extrusion. We also recycle 90% of the plastic off-cuts recovered during production.

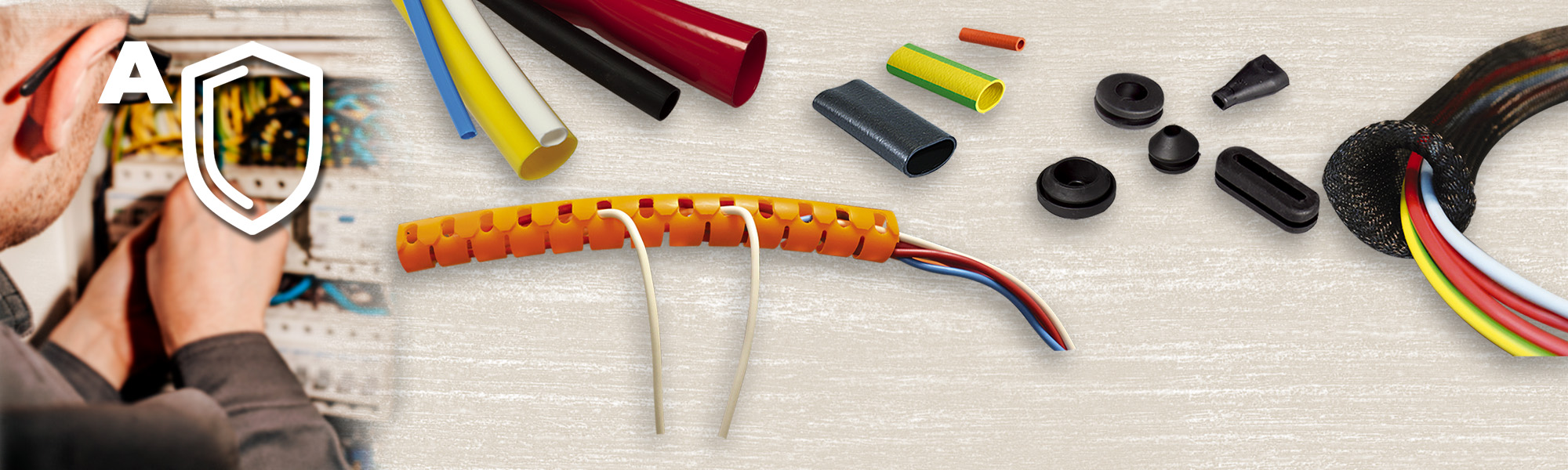

In the rubber workshop, we mould rubber parts (grommets, protectors, caps, feet and washers) using several presses. We precisely design all the moulds needed to produce our moulded parts.

Flexible extrusion and injection workshops

In the flexible extrusion workshop, we extrude materials for the manufacture of sleeves, profiles, identification rings, PLIO markers etc. Our materials central store automatically feeds the various production machines.

Our thermoplastic injection-moulded parts, such as cable ties, grommets and caps, are manufactured in the injection-moulding workshop.

LAUWPLAST – Rigid extrusion

The LAUWPLAST site manufactures cable and installation trunking, PLIOLINE protective channel, and profiles for distribution boxes. Using extruders and then punching machines, we carry out the preforming and finishing work on our products.

Braiding workshop

In the braiding workshop, we manufacture PLIOSIL expandable braided sleeving. We invite you to watch a video showing the entire manufacturing process.

Tools workshop

In the tools workshop, we assemble the tools essential to your work all around the cable: stripping or crimping tools etc. We also develop specific tools to meet your requirements.

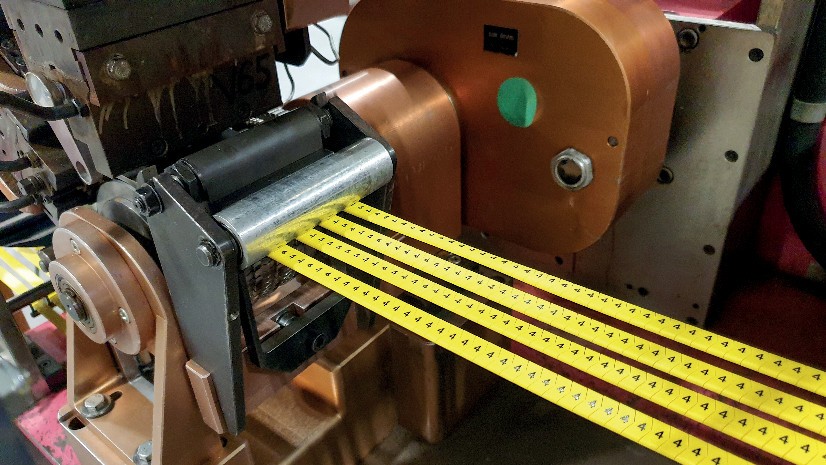

Printing and identification workshops

In the printing and marking workshops, we manufacture standard and customised identification processes: marker cards, identification markers, heat-shrink identification sleeves, printed carriers, laser identification, etc.

Several identification techniques are used, including inkjet, hot printing, thermal transfer, letterpress, screen printing, embossing and laser engraving and cutting. We also print our catalogue which you can download in PDF format from our website.

Packaging workshop

In the packaging workshop, we prepare and package all SES-STERLING products using packaging machines and the expertise of our staff.

Stock / Shipping

This is where our products are stored, your orders prepared and dispatched straight away. Our automated storage system ensures that your orders are prepared efficiently for delivery as quickly as possible.

Other articles that may interest you:

Relocation of SES-STERLING S.A.

The Hésingue 2020 project, which is the move of SES-STERLING S.A., will mark a major…

Inauguration of LAUWPLAST: return on its story

LAWPLAST, located in a building bought in 1991 by the SES-STERLING group, has just completed…